Five years ago, three orcas died in the Nushagak River. One was pregnant, and Bristol Bay area scientists, students, and educators have been working to make a plastic model of the fetal orca's skeleton.

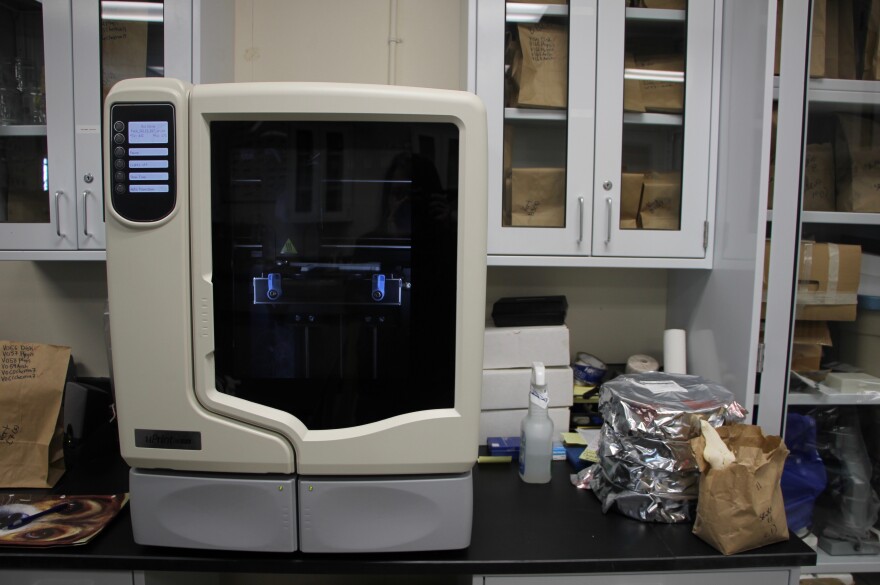

A machine the size of a mini-fridge sits on the counter of a college science lab. Three half-constructed plastic models of fetal orca bones are visible through the glass front. The 3-D printer’s extruder moves across the models, adding plastic layer by layer. It whirs, hums, and beeps like a “Star Wars” droid.

In September of 2011, three killer whales puzzled biologists by traveling about 70 miles up the Nushagak River. Orca’s natural habitat is saltwater. Sometimes they swim up the freshwater river for salmon, but not that far. By October all three whales had died. That raised the question of what to do with the bodies, which led to an unusual science project.

One orca was pulled ashore, and NOAA scientists performed a necropsy. When they discovered the whale was pregnant, they saved both her skeleton and the skeleton of the fetus. But preserving the fetus was complicated because its bones hadn’t ossified and fused together yet.

Kent Winship teaches construction and runs the fabrication laboratory at the University of Alaska Fairbanks Bristol Bay Campus. He has helped oversee work on the solution to that problem.

“It was basically a bag of bones with skin on it, just like a big trash bag full of partially formed cartilage, and not all the way meshed together bones,” says Winship. “This is all cartilage, so it’s going to decay. What they decided to do was 3-D scan them.”

So the Nushagak Orca Articulation Project was born. The Dillingham City School District, Bristol Bay Campus, and Nunamta Aulukestai have worked in partnership to clean, categorize, scan, and print the fetal skeleton’s hundreds of bones.

The project brought high school student Cheyenne Roehl onboard two years ago to scan bones. She works in the campus lab three hours every weekday. A few other people have been involved in scanning over the years, but Winship says that Roehl has done the bulk of the work.

Her job is to create 3-D digital models of the bones in a computer aided drafting program.

“I get one of the bones, and I put it on the scanner,” she says, explaining her process. “We have to get multiple scans, and then align them together. And then we make sure that it looks like the bone, and then we get a finalized water tight model…I’m making it sound a lot more simple than it actually is.

It’s time consuming work. If a bone has a lot of holes, protrusions, or facets, it can take numerous scans to capture all the angles. Each scan takes about 20 minutes.

Roehl pulls a piece of the orca’s skull from one of tall cabinets where bones are stored in jars and paper bags.

She holds it, turning it over and running her fingers along its different angles.

“I see a lot of holes and places that scanned very well to have a lot more detail for the scan because we use a laser, and if it’s slanted a little bit, the scanner won’t be able to pick up that data.”

When she has the scans, Roehl joins the images to form one 3-D model. Then she prints it and organizes it with the other printed bones.

The project reached an important milestone this week. Roehl finished scanning, and she’s about to finish printing the last of the roughly 300 whale bones.

Then it will be time for the jigsaw phase of this project. Project leaders with the university, school district, and Nunamta Aulukestai are developing plans to begin constructing the skeleton out of the model bones. They aim to involve students in this stage of the work as well. Fully assembled the killer whale fetus will be about 6-feet long.

Roehl reflects on the hundreds of hours she and other students have put in over the years. She says that it’s the idea of seeing this orca skeleton completed that keeps up the momentum.

“It’s really exciting because you know that they’re going to be turned into a 3-D model skeleton, and that will be beautiful.”

Contact the author at 907-842-5281 or avery@kdlg.org